Introduction

Understanding chemical reactions lies at the heart of organic chemistry. One such reaction, the hydrolysis of methyl formate (HCOOCH₃) with water (H₂O), exemplifies the principles of ester hydrolysis. This reaction is not only pivotal in academic contexts but also has significant industrial applications, particularly in the production of formic acid (HCOOH) and methanol (CH₃OH). But how does the reaction work, and why does (hcooch ch2 h2o) matter in the real world?

This blog post breaks down the HCOOCH CH2 H2O reaction mechanism, its industrial relevance, and safety considerations for handling reactants and products. By the end, you’ll better appreciate how a seemingly simple reaction powers industries that produce fuels, textiles, pharmaceuticals, and more.

What Is the Hydrolysis of Methyl Formate?

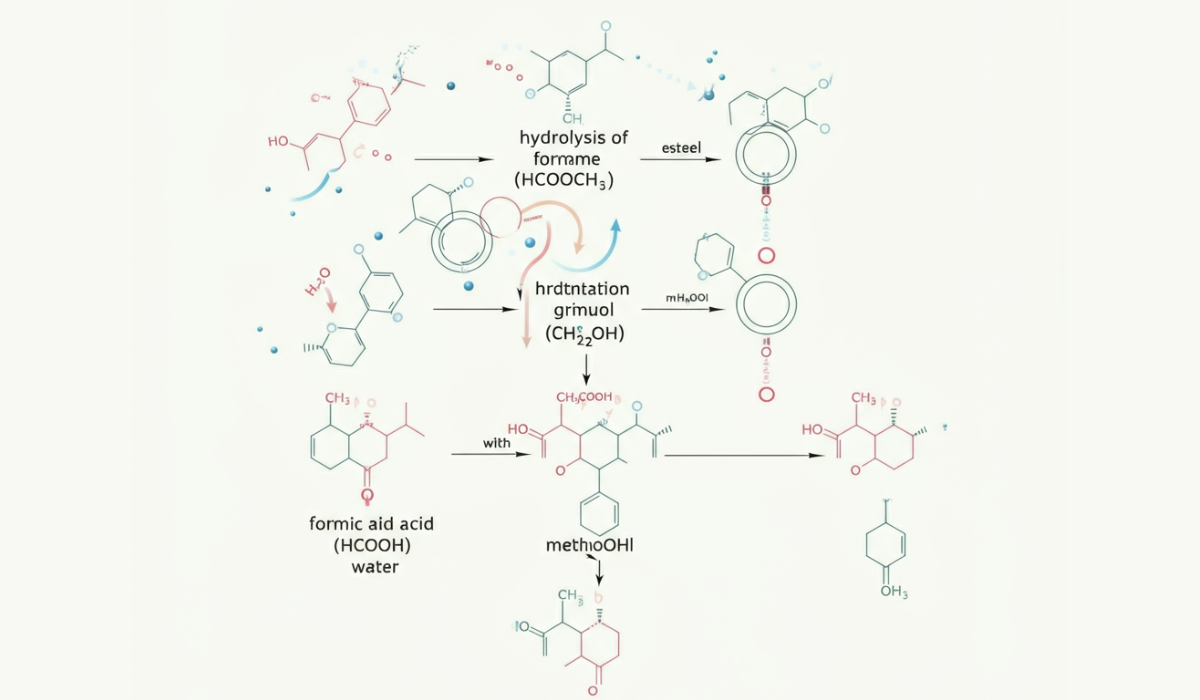

The hydrolysis of methyl formate involves breaking the ester bond of HCOOCH₃ in the presence of water (H₂O) to yield formic acid and methanol. Represented by the equation:

HCOOCH₃ + H₂O → HCOOH + CH₃OH

This reaction is a classic example of nucleophilic substitution, where water acts as a nucleophile attacking the electrophilic carbonyl group in methyl formate.

Reaction Conditions for Hydrolysis

- Acidic Hydrolysis

Acidic catalysts, such as sulfuric acid (H₂SO₄), protonate the carbonyl oxygen in HCOOCH₃, making it highly reactive and facilitating water’s nucleophilic attack. Acidic hydrolysis is widely used in industrial processes due to its efficiency and superior yield of products.

- Basic Hydrolysis

Less common on an industrial scale, basic hydrolysis uses a strong base like sodium hydroxide (NaOH). While effective, it can lead to challenges such as byproducts requiring neutralization.

Reaction Mechanism Under Acidic Conditions

The process occurs in several defined steps and can feel complex, but breaking it down helps demystify the reaction:

- Protonation of the Carbonyl Group

The carbonyl oxygen in methyl formate is protonated by the acid catalyst, increasing the carbonyl carbon’s susceptibility to nucleophilic attack.

- Nucleophilic Attack by Water

A water molecule attacks the carbonyl carbon, forming an intermediate with a tetrahedral structure.

- Intermediate Breakdown

The tetrahedral intermediate undergoes a proton transfer, resulting in the cleavage of the ester bond. This produces protonated formic acid and methanol.

- Deprotonation of Formic Acid

The protonated formic acid then loses a proton to form the stable product, HCOOH, alongside CH₃OH.

Factors Influencing the Reaction

Several factors affect the efficiency and rate of the hydrolysis reaction.

- Catalyst Presence

Acidic catalysts such as sulfuric acid accelerate the reaction by lowering activation energy.

- Temperature

Higher temperatures speed up the reaction but need careful control to avoid unwanted side reactions or product decomposition.

- Water Content

Using an excess of water drives the reaction equilibrium toward product formation (Le Chatelier’s Principle).

- Reaction Conditions

Acidic hydrolysis is preferred for industrial-scale processes due to higher yields compared to basic conditions.

Industrial Applications of the Hydrolysis of Methyl Formate

The products of methyl formate hydrolysis, formic acid (HCOOH) and methanol (CH₃OH), are incredibly valuable in various industries.

1. Formic Acid Applications

Formic acid, also known as methanoic acid, plays a significant role in several areas, including:

- Textile and Leather Processing: Used for dyeing fabrics and tanning leather.

- Agriculture: Acts as a preservative and antibacterial agent in livestock feed.

- Chemical Synthesis: Serves as an intermediate in producing formate salts, preservatives, and other chemicals.

2. Methanol Applications

Methanol is one of the most versatile chemicals, making it vital in numerous industries.

- Fuel Production: Methanol is used as a fuel additive and in the production of biodiesel.

- Chemical Synthesis: It serves as a building block for formaldehyde, acetic acid, and other compounds.

- Solvent: Widely used as a solvent in the paint, coating, and pharmaceutical industries.

Practical Insights into the Production Process

For the large-scale hydrolysis of methyl formate, industries focus on optimizing conditions for maximum yield while adhering to safety protocols. Below are some key considerations critical to the process.

Efficiency Optimizers

- Excess Water: Drives the equilibrium toward product formation.

- Acidic Catalysts: Enhances the speed and yield of the reaction.

- Controlled Temperature: Balances reaction rate with product stability.

Challenges in Basic Hydrolysis

While basic hydrolysis can be effective, it creates challenges in the form of byproducts that demand additional steps for neutralization. This adds time and costs to the process, explaining why acidic conditions are more common.

Safety Suggestions

Handling the reactants and products of this reaction requires care due to their properties.

- Methyl Formate: Highly flammable and toxic upon inhalation or ingestion.

- Methanol: Toxic and flammable, requiring adequate ventilation and protective measures.

- Formic Acid: Corrosive and capable of causing burns or severe skin/eye damage.

Why This Reaction Matters

The hydrolysis of methyl formate has significance beyond its practical implications. It serves as an instructive example of fundamental principles in organic chemistry, such as nucleophilic substitution and reaction kinetics.

Furthermore, understanding such reactions enables industries to pioneer large-scale chemical production while maintaining adherence to environmental and safety standards.

Ensuring Efficiency and Safety in Industrial Applications

The hydrolysis of methyl formate into formic acid and methanol represents more than a chemical equation. It is a practical demonstration of how fundamental chemistry supports real-world industries, from agriculture to fuel production, all while showcasing the potential for optimizing efficiency and upholding safety.

When managed with precision, this reaction illustrates how chemistry can rise to meet global challenges in industrial supply chains and sustainable practices.